- bathrooms

- Accessible Bathrooms

- Support Rails

- Walkin Bath

Accessible Bathrooms

Accessible Bathrooms

- Bath Tubs

- Alcove Bathtubs

- Bath Tubs

- Corner Bathtubs

- Drop In Bathtubs

- Free Standing Bathtubs

- Jacuzzi Whirlpool

Bath Tubs

Bath Tubs

Bath Tubs

Bath Tubs

Bath Tubs

Bath Tubs

- Bathroom Accessories

- Baskets

- Bath Stools

- Bathroom Wall Shelves

- Bottle Trap

- Hair Dryer Holders

- Hand Dryer

- Health Faucets

- Liquid Soap Dispensers

- Mirrors

- Robe Hooks

- Shower Curtain

- Shower Rails

- Soap Dishes

- Toilet Brush Holders

- Toilet Brushes

- Toilet Roll Holders

- Toilet Seats

- Toothbrush Holders

- Towel Holders

- Tumbler Holders

- Waste Bins

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

Bathroom Accessories

- Bathroom Furniture

- Bathroom Cabinets

- Vanity Units

- Washbasin Countertops

Bathroom Furniture

Bathroom Furniture

Bathroom Furniture

- Bathroom Lighting

- Bathroom Wall Lamps

- Mirror Lamps

- Sensory Lights

Bathroom Lighting

Bathroom Lighting

Bathroom Lighting

- Faucets

- Angle Valves

- Bath Faucets

- Bathtub Faucets

- Bidet Faucets

- Diverters

- Faucet Spares

- Sensor Faucet

- Shower Mixers

- Spouts

- Washbasin Faucet

Faucets

Faucets

Faucets

Faucets

Faucets

Faucets

Faucets

Faucets

Faucets

Faucets

- Laundry

- Dryers

- Laundry Baskets

- Utility Sinks

- Washing Machines

Laundry

Laundry

Laundry

Laundry

- Sanitary Ware

- Bidets

- Indian Toilets

- Toilets

- Toilets

- Washbasins

Sanitary Ware

Sanitary Ware

Sanitary Ware

Sanitary Ware

Sanitary Ware

- Showers

- Body Jets

- Electric Showers

- Hand Showers

- Hand Showers Holders

- Overhead Showers

- Rain Showers

- Shower Accessories

- Shower Arms

- Shower Cabins

- Shower Drains

- Shower Panels

- Shower Trays

Showers

Showers

Showers

Showers

Showers

Showers

Showers

Showers

Showers

Showers

Showers

Showers

- Spares & Fittings

- Ball Cock

- Cartridge

- Chand Set

- Nozzle

- Washing Machine Adaptor

Spares & Fittings

Spares & Fittings

Spares & Fittings

Spares & Fittings

Spares & Fittings

- Toilets

- Flush Plates

- Flush Tanks

- Flush Valve

- Flushing Sytems

- One Piece Toilet

- Two Piece Toilet

- Urinal Push Cock

- Urinal Sensor

- Urinals

- Wall Hung Wc

- Wall Hung Wc (archive)

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

Toilets

- Washbasins

- Built In Basins

- Pedestal Basins

- Table Top Basins

- Wall Hung Basins

Washbasins

Washbasins

Washbasins

Washbasins

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

bathrooms

- Accessible Bathrooms

- electrical

- Appliances

- Air Conditioners

- Fans

- Humidifiers

- Solar Water Heater

- Water Heaters

Appliances

Appliances

Appliances

Appliances

Appliances

- Circuit Breakers

- Conduit, Boxes & Fittings

- Conduit Fittings

- Conduit Pipes

- Wiring Boxes

Conduit, Boxes & Fittings

Conduit, Boxes & Fittings

Conduit, Boxes & Fittings

- Fans

- Ceiling Fans

- Exhaust Fan

- Pedestal Fans

- Table Fans

- Wall Fans

Fans

Fans

Fans

Fans

Fans

- Fire Prevention Safety

- Fire Doors And Closures

- Fire Escape And Safety Stairs

- Fire Fighting Systems And Extinguishers

- Fireproof Walls And Ceilings

Fire Prevention Safety

Fire Prevention Safety

Fire Prevention Safety

Fire Prevention Safety

- Home Automation

- Home Automation Systems

- Motion Sensors

- Switch Controllers

- Touch Screens

- Voice Activated Switches

Home Automation

Home Automation

Home Automation

Home Automation

Home Automation

- Security

- Access Control Systems

- Cctv Camera

- Cctv System

- Cctv Wires

- Digital Safes

Security

Security

Security

Security

Security

- Switches And Sockets

- Adaptors

- Door Bell

- Plug Tops

- Regulators

- Sockets

- Switch Gears

- Switch Plates

Switches And Sockets

Switches And Sockets

Switches And Sockets

Switches And Sockets

Switches And Sockets

Switches And Sockets

Switches And Sockets

- Wires And Cables

- Electrical Cables

- Low Tension Wires

- Switches And Sockets

Wires And Cables

Wires And Cables

Wires And Cables

electrical

electrical

electrical

electrical

electrical

electrical

electrical

electrical

electrical

- Appliances

- furniture

- Bars

- Bar Cabinets

- Bar Stools

- Bottle Racks

Bars

Bars

Bars

- Beds

- Day Beds

- Double Beds

- King And Queen Beds

- Single Beds

- Storage Beds

Beds

Beds

Beds

Beds

Beds

- Chairs And Sofas

- Arm Chairs

- Dining Chairs

- Easy Chairs

- Lounge Chairs

- Massage Chairs

- Ottomans

- Reclining

- Sectionals

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

Chairs And Sofas

- Office

- Executive Chairs

- Filing Cabinets

- Office Booths

- Office Chairs

- Office Desks

- Office Partions

- Office Stools

- Office Storage Units

- Office Workstations

- Visitors Chairs

Office

Office

Office

Office

Office

Office

Office

Office

Office

Office

- Partitions

- Internal Partitions

Partitions

- Soft Furnishings

- Carpets

- Cushions

- Fabrics

- Mattresses

- Rugs

Soft Furnishings

Soft Furnishings

Soft Furnishings

Soft Furnishings

Soft Furnishings

- Storage Units

- Book Cases

- Chests Of Drawers

- Display Cabinets

- Dressers

- Side Boards

- Storage Walls

- Tv Cabinets

- Walkin Wardrobes

- Wall Cabinets

- Wardrobes

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

Storage Units

- Tables, Benches, Stools

- Bedside Tables

- Benches

- Coffee Tables

- Dining Tables

- Foot Stools

- Writing Desks

Tables, Benches, Stools

Tables, Benches, Stools

Tables, Benches, Stools

Tables, Benches, Stools

Tables, Benches, Stools

Tables, Benches, Stools

furniture

furniture

furniture

furniture

furniture

furniture

furniture

furniture

- Bars

- hardware

- Cabinet Hadware

- Cabinet Handles & Knobs

- Drawer Channels

Cabinet Hadware

Cabinet Hadware

- Door Accessories

- Door Closers

- Door Stoppers

- Door Systems

Door Accessories

Door Accessories

Door Accessories

- Fasteners

- Dowel

- Nails

- Screws

- Wall Hooks

Fasteners

Fasteners

Fasteners

Fasteners

- Hinges

- Door Hinges

- Hydraulic Hinges

- Shutter Hinges

- Soss Hinges

Hinges

Hinges

Hinges

Hinges

- Kitchen Hardware

- Drawer Organiser

- Drawer Systems

- Roller Shutter

Kitchen Hardware

Kitchen Hardware

Kitchen Hardware

- Locks

- Cam Locks

- Digital Locks

- Furniture Locks

- Latch Locks

- Mortise Locks

- Rim Locks

Locks

Locks

Locks

Locks

Locks

Locks

- Other Hardware

- Bed Fittings

- Drawer Mats

- Floor Spring

- Skirtings

Other Hardware

Other Hardware

Other Hardware

Other Hardware

- Wardrobe Hardware

- Wardrobe Fittings

- Wardrobe Sliding System

Wardrobe Hardware

Wardrobe Hardware

hardware

hardware

hardware

hardware

hardware

hardware

hardware

hardware

- Cabinet Hadware

- kitchen

- Cabinets And Counters

- Cabinets & Drawer Accessories

- Kitchen Baskets

- Kitchen Cabinets

- Kitchen Drawers

- Kitchen Shelves

- Modular Kitchens

- Pull Outs

Cabinets And Counters

Cabinets And Counters

Cabinets And Counters

Cabinets And Counters

Cabinets And Counters

Cabinets And Counters

Cabinets And Counters

- Kitchen Accessories

- Dish Holders

- Drains

Kitchen Accessories

Kitchen Accessories

- Kitchen Appliances

- Chimneys

- Cooking Ranges

- Dishwashers

- Garbage Disposals

- Hobs

- Mini Fridges

- Mixer Grinder

- Ovens

- Refrigerators

- Warming Drawers

- Water Purifiers

- Wine Coolers

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

Kitchen Appliances

- Kitchen Faucets

- Sink Taps

Kitchen Faucets

- Kitchen Sinks

- Double Bowl Sinks

- Kitchen Faucets

- Single Bowl Sinks

- Sink Accessories

- Sinks

Kitchen Sinks

Kitchen Sinks

Kitchen Sinks

Kitchen Sinks

Kitchen Sinks

kitchen

kitchen

kitchen

kitchen

kitchen

- Cabinets And Counters

- lighting

- Accessories

- Light Bulbs

- Linear Lighting Profiles

- Spot Lights

- Steplights

- Strip Lights

Accessories

Accessories

Accessories

Accessories

Accessories

- Decorative Interior Lighting

- Ceiling Light

- Chandelier Lights

- Downlights

- Floor Lamps

- Furniture Lighting

- Lamp Shades

- Pendant Lamps

- Table Lamps

- Track Lights

- Wall Lamps

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

Decorative Interior Lighting

- Decorative Outdoor Lighting

- Bollard Lights

- Lamp Posts

- Outdoor Ceiling Lamps

- Outdoor Floodlights

- Outdoor Floor Lamps

- Outdoor Pendant Lamps

- Outdoor Spot Lights

- Outdoor Wall Lamps

- Street Lamps

- Underwater Lamps

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

Decorative Outdoor Lighting

- Industrial

- Industrial Lights

Industrial

lighting

lighting

lighting

lighting

- Accessories

- materials

- Building Blocks

- Aac Blocks

- Adobe Blocks

- Blocks

- Bricks

- Fly Ash Bricks

- Jaalis

- Red Bricks

Building Blocks

Building Blocks

Building Blocks

Building Blocks

Building Blocks

Building Blocks

Building Blocks

- Carpentry

- High Pressure Laminates

- Laminates

- Plywoods

- Veneers

- Wood Decking

- Wood Slabs

Carpentry

Carpentry

Carpentry

Carpentry

Carpentry

Carpentry

- Ceilings

- Coffered Ceiling

- Conventional Ceiling

- Suspended Ceilings

Ceilings

Ceilings

Ceilings

- Cement Admixtures

- Admixtures

- Cement

Cement Admixtures

Cement Admixtures

- Construction Materials

- Concrete

- Stamp Concrete

Construction Materials

Construction Materials

- Doors

- Aluminium Doors

- Door Handles

- Doors

- Fire Proof Doors

- Glass Doors

- Solid Wood Doors

- Upvc Pvc Doors

Doors

Doors

Doors

Doors

Doors

Doors

Doors

- Facades

- Clay Facades

- Concrete Facades

- Facade Cladding

- Glass Facades

- Metal Facades

- Stone Facades

- Wood Facades

Facades

Facades

Facades

Facades

Facades

Facades

Facades

- Floorings

- Concrete Flooring

- Floorings

- Terrazzo Flooring

- Wooden Flooring

Floorings

Floorings

Floorings

Floorings

- Glass

- Architectural Glass

- Clear Glass

- Fluted Glass

- Frosted Glass

- Glass Blocks

- Glass Fittings

- Structural Glass

Glass

Glass

Glass

Glass

Glass

Glass

Glass

- Hardware

- Door Accessories

- Locks

Hardware

Hardware

- Inner Walls

- Interior Walls

- Acoustic

- Aluminium Profiles

- Cement Fiber Board

- Cement Particle Board

- Concrete Panel

- Fluted Panels

- Mdf Boards

- Metal Composite Panels

- Oriented Strand Board (osb)

- Plaster Boards

- Pvc Boards

- Wall Panels

- Wallpapers

- Wood Panels

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

Interior Walls

- Metal Structures

- Angles & Channels

- Light Weight Truss

- Pre Fabricated Structures

- Stainless Steel Profile

- Steel

- Tmt

Metal Structures

Metal Structures

Metal Structures

Metal Structures

Metal Structures

Metal Structures

- Paints And Plasters

- Enamels

- Exterior Paints

- Interior Paints

- Paints

- Primers

- Putty

- Wood Coatings

Paints And Plasters

Paints And Plasters

Paints And Plasters

Paints And Plasters

Paints And Plasters

Paints And Plasters

Paints And Plasters

- Roofs

- Poly Carbonate Sheets

- Roof Panels

- Roof Shingles

- Roof Sytems

- Roof Tiles

- Water Proofing

Roofs

Roofs

Roofs

Roofs

Roofs

Roofs

- Scaffolding

- Scaffolding Products

Scaffolding

- Shades

- Blinds

- Invisible Blinds

- Louvers

- Nets

- Shutters

- Sun Shaders

Shades

Shades

Shades

Shades

Shades

Shades

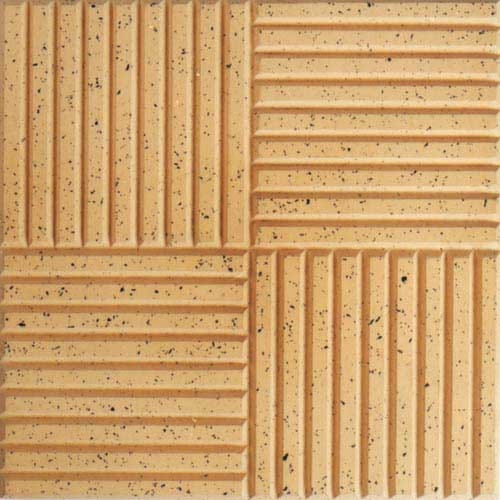

- Stones And Tiles

- Brick Tiles

- Color And Gloss Enhancers

- Corian

- Floor Tiles

- Granite

- Grouts

- Marble

- Mosaic Chips

- Mosaics

- Natural Stone

- Paver Tiles

- Quartz

- Screeds

- Sealers And Impregnators

- Stone And Tile Adhesives

- Swimming Pool Tiles

- Wall Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

Stones And Tiles

- Water Proofing

- Liquid Coating

- Sealants

Water Proofing

Water Proofing

- Windows

- Automated Windows

- Casement Windows

- Sash Windows

- Sliding Windows

- Windows

Windows

Windows

Windows

Windows

Windows

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

materials

- Building Blocks

- mechanical

- Elevators

- Elevators & Escalators, Travelators

Elevators

- Hvac

- Al Ducting

- Boilers And Burners

- Fire Places

- Floors And Wall Heaters

- Radiators

- Stoves

- Ventilations

Hvac

Hvac

Hvac

Hvac

Hvac

Hvac

Hvac

mechanical

mechanical

- Elevators

- outdoors

- Fireplaces And Heaters

- Fire Baskets

- Outdoor Fireplaces

- Outdoor Heaters

Fireplaces And Heaters

Fireplaces And Heaters

Fireplaces And Heaters

- Garden Awnings

- Awnings

- Garden Gazebos

- Pergolas

- Winter Gardens

Garden Awnings

Garden Awnings

Garden Awnings

Garden Awnings

- Gardening And Accessories

- Artificial Grass

- Greenhouses

- Landscape Edging

- Outdoor Greenwalls

- Planters

- Sprinklers

- Vertical Gardening Trellises

Gardening And Accessories

Gardening And Accessories

Gardening And Accessories

Gardening And Accessories

Gardening And Accessories

Gardening And Accessories

Gardening And Accessories

- Gates & Fences

- Outdoor Flooring

- Decking

- Decorative Chippings

- Decorative Pebbles

- Lawn Edging

- Outdoor Floor Tiles

- Paving Blocks

- Synthetic Grass Surfaces

Outdoor Flooring

Outdoor Flooring

Outdoor Flooring

Outdoor Flooring

Outdoor Flooring

Outdoor Flooring

Outdoor Flooring

- Outdoor Furniture

- Garden Armchairs

- Garden Benches

- Garden Chairs

- Garden Daybeds

- Garden Hanging Chair

- Garden Poufs

- Garden Sofas

- Hammocks

- Hanging Chairs

- Outdoor Cushions

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

Outdoor Furniture

- Solar

- Solar Gyser

- Solar Lights

- Solar Panels

- Solar Roof

- Solar Street Lights

Solar

Solar

Solar

Solar

Solar

- Swimming Pools Tubs Showers

- Outdoor Hot Tubs

- Outdoor Showers

- Pool Covers

- Pool Equipments

- Pool Liners

- Swimming Pool Heatings

- Swimming Pools

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

Swimming Pools Tubs Showers

outdoors

outdoors

outdoors

outdoors

outdoors

outdoors

outdoors

outdoors

- Fireplaces And Heaters

- plumbing

- Fittings

- Agriculture Fittings

- Swr Fittings

- Water Pipe Fittings

Fittings

Fittings

Fittings

- Pipes

- Agriculture Pipes

- Swr Pipes

- Water Pipes

Pipes

Pipes

Pipes

- Plumbing Hardware

- Connection Pipe

- Drain Cleaner

- Flange

- Nipple

- Pipes And Fittings

- Pumps And Motors

- Rust Remover

- Solvent Cement

- Tapes

- Waste Pipe

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

Plumbing Hardware

- Pumps

- Booster Pumps

- Centrifugal Pumps

- Open Well Pumps

Pumps

Pumps

Pumps

- Tanks

- Overhead Tanks

- Sewage Tanks

Tanks

Tanks

- Water Systems

plumbing

plumbing

plumbing

plumbing

plumbing

plumbing

- Fittings

- Brands

- Consultants

Get the latest products and offers!

Don't miss out on the latest brand and product launches and offers.